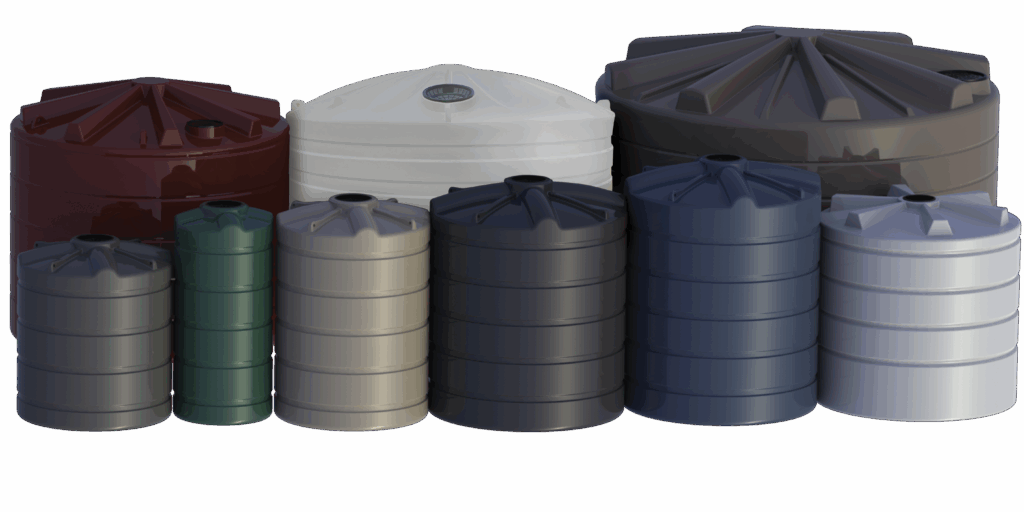

Rainwater Tanks Manufactured in South Australia

Rainwater TanksBuilt and designed to last. Maxiplas tanks are designed with a lifetime in mind. Our rotational moulding means Maxiplas tanks are:

- UV Stabilised

- BPA free

- Seamless

- Durable

- Recyclable

We Specialise in Rotational Moulding

Maxiplas has designed and developed its own superior range of rain water tanks and storm water harvesting products.

What is Rotational moulding?

Rotational moulding is a high-temperature, low-pressure manufacturing process that produces seamless, hollow plastic parts by heating a polymer powder inside a rotating mould. The mould rotates on two perpendicular axes, causing the softened polymer to uniformly coat the interior surface and form a single-piece structure.

The process consists of four phases: loading the mould with polymer powder, heating and rotating the mould to melt and distribute the material, cooling the mould to solidify the part, and removing the finished product. The absence of external pressure during moulding results in stress-free parts with even wall thickness and minimal material waste. Rotational moulding enables the economical production of large, durable, and complex hollow items, such as tanks, containers, and playground equipment, with low tooling costs and broad design flexibility. The process is highly sensitive to variables like polymer particle size, ambient conditions, and precise temperature control, which influence mechanical properties and dimensional accuracy. Polyethylene is the predominant material due to its thermal stability and structural integrity after cooling.

Download Our Tank Brochure

Explore our complete range of South Australian–made rainwater tanks. Inside you’ll find detailed sizes, colours, fittings, and installation information to help you choose the right tank.